The Temple of VTEC Asia

Short Technical Overview Series

New VTEC Implementation : SOHC i-VTEC on the R18A

The new R18A engine used on the 8th Gen Civic is the newest engine introduced by Honda. This engine introduces the SOHC i-VTEC implementation, an entirely new idea of VTEC implementation. We take a look at the technical aspects of this new VTEC implementation.

R-Series 'SOHC i-VTEC' Operating Principle

Honda's SOHC i-VTEC implementation works on a simple principle and this principle is that when we drive a car, we usually engage one of two distinct 'driving styles' or modes. Under normal driving and aggressive driving, we demand performance from the engine: good off-the-line pick-up, instant throttle response, strong steady acceleration, and so forth. Then when the conditions allow it, like on the expressways, we often switch to a relaxed mode: steady speed light-throttle cruising, probably listening to nice music on the stereo or engaging in stimulating conversation with our passengers. Under such conditions, performance is the last thing on our mind (unless we want to overtake). Such conditions are also most conducive to fuel economy and consequently we expect good fuel economy from the engine as well.

To understand the design objective of the R18A SOHC i-VTEC, we look at light throttle situations described above, when the car is running leisurely or at 'light load' (no hard demands on power or performance). In such conditions, the engine often spins lazily at around 2500 to 3500rpm and throttle pedal pressure is extremely light. Consequently the throttle butterfly is almost closed, especially at legal highway speeds (between 80, 90 or at most 110kph in most countries). Now when the pistons are running, they will need to suck air from the intake manifold and through the almost closed throttle butterfly. However the almost closed throttle buttefly will be resisting the sucking / pumping action of pistons. This wastes energy and is called "Pumping Loss".

If we think about it, this situation is actually very ironic when we look at it from the practical point of view. Here is the situation where we are able to, and expects the engine to produce great fuel economy. But the almost closed throttle butterfly also introduces the largest amount of pumping restriction - and power loss - to the engine. So the almost closed throttle butterfly actually negatively impacts the engine's operating efficiency and thus its fuel economy, at a time where the operating environment is most conducive for the engine to deliver good fuel economy.

In a case of clearly thinking outside of the box, Honda's R&D engineers for the Rseries tackled this imbalance directly and introduced the Rseries's SOHC i-VTEC implementation. So the Rseries SOHC i-VTEC is a fuel economy implementation that works by targetting at the reduction of pumping losses in the engine in driving conditions which are most conducive to fuel economy. Now the R18A engine can truly be seen as a 'dual mode' engine with clear-cut normal driving and 'economy driving' modes.

SOHC i-VTEC Implementation (R-Series Engine)

As explained above, under so-called low-load conditions (steady speed cruising within speed limits, down-hill, generally light to very light throttle driving) on a conventional engine, the throttle valve is normally partly closed to control or limit the intake volume of the fuel-air mixture. The air-flow restriction that is incurred due to intake resistance in such conditions is one of the biggest factor that leads to reduced engine efficiency, through pumping losses explained above. With the R18A SOHC i-VTEC mechanism, Honda's R&D engineers introduced the idea of controlling the amount of air entering the combustion chamber via other means instead of the throttle butterfly. This is done via a combination of both valve timing and an exploitation of the property of the 4-stroke cycle and a new Drive By Wire (DBW) system.

First, the intake valve closure timing is delayed to a very long period, way into the piston upstroke part of the cycle. The idea is to allow air to enter the cylinders freely, without using the throttle butterfly to artificially restrict air-flow. Then by opening the intake valves right through to the piston upstroke part of the cycle, the excess amount of air-fuel mixture that is in the cylinder will be expelled by the upward stroke of the pistons out through the intake valves and back into the intake manifold. When the amount of air-fuel mixture left remaining in the cylinder/combustion chamber is the desired amount, only then will the intake valves be closed. So instead of using the throttle butterly to control or limit the amount of air entering the engine, we allow the air to enter the cylinders and then push the unwanted amount out of the cylinders. So the exact amount of air we want is now controlled by the timing of the intake valve closure. In this way, the throttle valve/butterfly is not used/needed and it is allowed to remain wide open even under low-load conditions. This contributes to a a major reduction in pumping losses - up to 16% reduction according to Honda's calcuations. Combined with comprehensive friction-reducing measures, this results in a significant increase in fuel efficiency for the engine itself.

|

|

The new DBW (Drive By Wire) system on the R18A now constitutes a major and crucial part of the R18A's SOHC i-VTEC mechanism. Firstly, it provides the high-precision control over the throttle valve required while the valve timing is being changed over, ensuring smooth driving performance that leaves the driver unaware of any torque fluctuations. Secondly, and more importantly, during the economy mode there is the unusual, and conflicting situation where while the throttle pedal is at an almost completely closed position, the throttle butterfly in the throttle body is in an almost completely opened position, the exact opposite ! However, this relationship only applies when the engine is running in economy mode, when VTEC has activated the fuel economy cam lobes. In normal running, the normal relationship between throttle pedal position and throttle butterfly opening remains, i.e. light throttle means small throttle butterfly opening, etc. Thus the SOHC i-VTEC mechanism used in the R18A is only possible with a DBW system.

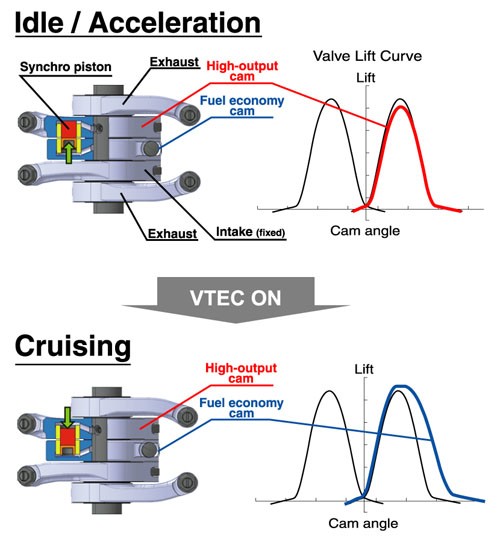

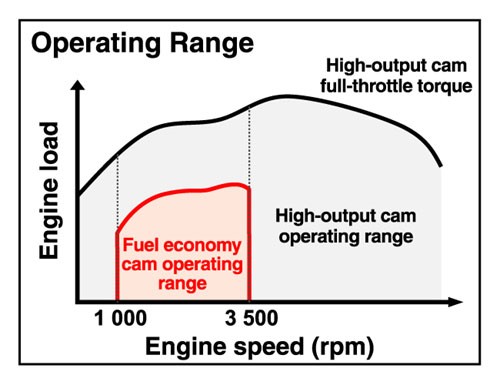

So the new SOHC i-VTEC implementation is an entirely new implementation, quite unlike those already in use. Under normal driving conditions, the R18A runs on its normal set of cam-lobes which in a completely reversed role, Honda calls the 'hot-cams'. So VTEC-off on the R18A means it can be considered to be running high cams. When the right conditions are acheived for fuel economy, VTEC engages the 2nd set, the 'low' or 'economy' cams. Thus VTEC-on on the R18A means it is running low cams. More importantly is VTEC engages the low-cams only if the right conditions for fuel economy are acheived. If they are never acheived, like when we are driving aggressively for the whole trip for e.g., VTEC will never open on the R18A. Thus it is a completely different idea from the VTEC implementations of old where VTEC will always open after a certain rpm, irregardless of the driving conditions. This is also the reason why Honda feels it is justified to call this new implementation an i-VTEC implementation, 'i' of course meaning 'intelligent'. This is because the engine/ECU is 'smart' enough to know if conditions are right or not for VTEC to engage. This new mode of operating is clearly illustrated in the 3-dimensional torque-rpm-driving load chart on the left (supplied by Honda). Note the standard torque curve. This is the line right at the top of the chart and VTEC never activates across this torque curve. On the other hand, VTEC opens across a fairly wide range of driving conditions, in the shaded portion inside the torque curve. So if our throttle pedal position or other critical driving conditions are outside the shaded portion, the R18A will not engage VTEC at all.

|

|

Now normal driving conditions means a torquey and quite powerful R18A engine, thanks to the relatively aggressive high (low) cams and the new variable length intake manifold and other friction reducing technologies in the engine. So the 1.8l R18A which is SOHC in configuration is able to deliver as much power as a typical 'performance' oriented 1.8l DOHC engine without any worries about compromising fuel economy. On the other hand, once the driving conditions permits, the ECU 'opens' VTEC on the R18A. Now the reduction in pumping losses acheived allows the R18A to sip fuel at a similar rate to a normal 1.5l engine.

According to Honda, they have managed to design the R18A to deliver an off-the-line acceleration performance equivalent to a 2.0-liter engine while also delivering a fuel economy approximately 6% better than the current 1.7-liter Civic engine (through its low friction loss technologies). This makes it one of the world’s most efficient 1.8-liter engine designs. In addition, when driving conditions are right, like during cruising, the new engine achieves particularly high fuel economy, on a par with that of a 1.5-liter engine when VTEC activates the fuel-economy mode.

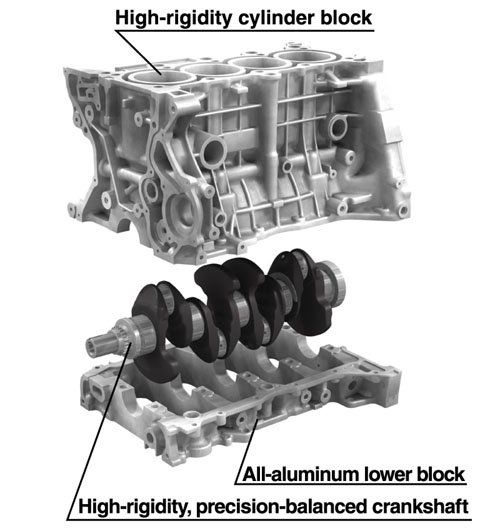

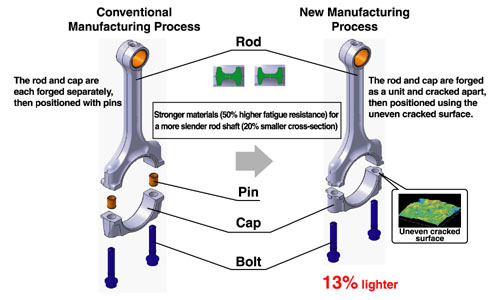

Other innovations have already been covered in our technical overview of the R18A engine. They include a variable-length intake manifold that delivers optimum inertia effect to further improve intake efficiency and piston oil jets that cool the pistons to suppress engine knock, thus allowing the R18A to run at a very high compression ratio of 10.5 :1 and this gives it powerful torque even at (lowish) rpm ranges typical in normal driving (especially when driving an autobox). Other items includes a new lower block construction resulting in a more rigid engine frame, aluminum rocker arms, high-strength cracked connecting rods, a narrow, silent cam chain, and other innovations make the engine more compact and lightweight. It is both lighter and shorter overall than the current Civic 1.7l engine, and quieter as well. Finally in the important area of emissions, the R18A also delivers cleaner emission performance by employing a 2-bed (2-stage) catalytic converter positioned immediately after the manifold and high-precision air-fuel ratio control (via the use of multiple air-flow sensors) to achieve emission levels 75% below 2005 Japanese government standards (based on Honda in-house testing). Again all these innovations are already covered in our R18A tech overview article.

Conclusion

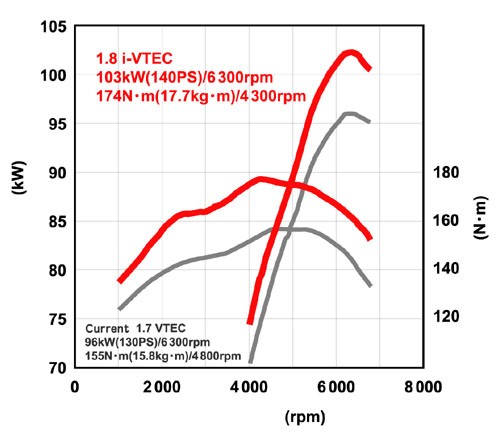

To conclude this article, let's quickly compare the rated power and torque of the R18A engine to similar engines including 'performance oriented' ones. The new R18A engine is rated for a maximum power output of 103kW (140PS) at 6,300rpm and maximum torque of 174N·m (17.7kg·m or 128lb-ft) at 4,300rpm. It is an undersquare design, with a bore & stroke of 81.0mm X 87.3mm, displacing a total of 1799c.c.

By comparison, the Toyota Corolla Altis, the Civic's arch-rival especially in Asia uses a 16V 1.8l engine in DOHC configuration and with VVT-i. This undersquare design also runs with a CR of 10.5 :1 and is rated for a max output of 100kW or 136ps at 6,000rpm and a max torque of 171Nm or 17.4kgm at 4,200rpm. Similarly the engine used on the Ford Focus which is 200c.c larger at 2.0l DOHC with 'Duratec', produces between 130 to 136ps with a max torque of 129 to 136 lb-ft. So we can see that within its market segment and againsts cars with similar design objectives, the new R18A presents a most competitive, in fact superior design.

Finally for an example of a 'performance oriented' engine, the 1.8l DOHC Twin-Spark engine used on the Alfa Romeos are rated for a max power output of 103kW or 140hp, the same rating as the R18A. Torque for this engine is 163Nm at 3,900rpm, around 10Nm lower than the R18A. Alfa Romeo rates the fuel consumption of this engine at 8.5 l/100 km on the combined cycle, 12.1 l/100 km urban cycle and 6.4 l/100 km extra-urban cycle. For comparison, the fuel economy figures for the JDM Civic 1.8S is rated for the standard JDM 10.15 cycle as between 16.2 to 17.0 km/l which works out to around 6.2 to 5.9 l/100 km.

This article completes our short technical overview series on the engines used on the Asian market 8G Civic. Hopefully TOVA readers will find this series to be a useful technical update and will also understand the true nature of Honda's new SOHC i-VTEC implementation, pioneered on the R18A engine.

Wong KN

October 2005

© Temple of VTEC Asia and Temple of VTEC