The Original Honda of Japan's K20A article

- The i-VTEC provides it all depending on engine load -

The DOHC i-VTEC utilizes smart valve control technology

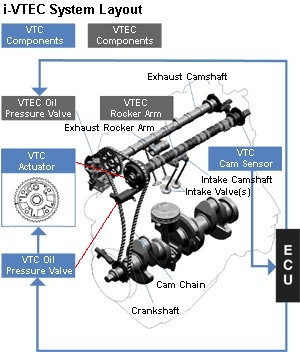

The i-VTEC system utilizes Honda's proprietary VTEC sytem and adds VTC (Variable Timing Control), which allows for dynamic/continuous intake valve timing and overlap control.

The demanding aspects of fuel economy, ample torque, and clean emissions can all be controlled and provided at a higher level with VTEC (intake valve timing and lift control) and VTC (valve overlap control) combined.

iVTEC = VTEC + VTC

Hopefully readers would have read my article on the new iVTEC and the basic operating principle that VTC or Variable Timing Control is based on. As Honda clearly stated in this K20A article, iVTEC is VTEC with VTC added. K20A uses a combination of VTEC-E and power-VTEC that switches between 12-valve economy mode and a 16-valve mode with a separate wild intake cam. VTC complements this VTEC variation. For the K20A engine however, outright power is not the sole objective of iVTEC, the other important parameters of fuel economy and emissions has been given equally important footing, a direction that Honda has always promoted in the past. This impossible balance of power and economy has previously only been realizeable in Honda's D15B 3-stage VTEC first used on the previous generation EK3 (and the D17A on the current Civic).

|

| VTC (Variable Timing Control

mechanism)

The VTC actuator, installed on the intake camshaft, is controlled by oil pressure, to allow for dynamic and continuous valve timing to fit the load of the engine. |

|

The iVTEC implementation

The K20A engine diagram explains the layout of the various components implementing iVTEC. I have intentionally edited the original diagram very slightly - the lines identifying the VTC components are rather faint and their orientation confusing. I have overlaid them with red lines. They identify the VTC actuator as well as the oil pressure solenoid valve, both attached to the intake camshaft's sprocket. The VTC cam sensor is required by the ECU to determine the current timing of the intake camshaft.

The VTEC mechanism on the intake cam remains essentially the same as those in the current DOHC VTEC engines except for an implementation of VTEC-E for the 'mild' cam. The K20A article covers that in some details later.

The VTC mechanism

Honda's pictorial representation of the VTC mechanism illustrates very clearly the operating principle of generic VVT - ie turning the camshaft in relation to the driving sprocket. However the actual VTC mechanism is unclear from the diagram. Readers should bear in mind that the generic VVT mechanism I described on the iVTEC article is just that - generic. Different manufacturers will implement the mechanism using different details. However, the important part is the introduction of a mechanism to isolate the camshaft from its driving sprocket and which also allows the relative rotational alignment between the two to be accurately controlled and continously changed.

From what little is available from the Honda illustration, it seems that Honda may have opted to use a gear and tooth mechanism on the sprocket itself to implement the ability to rotate the sprocket in relation to the camshaft (or vice versa depending on how you look at it.)

| Additionally, the intake manifold length can be

adjusted.

Combined with the DOHC i-VTEC, in order to obtain both ample low/mid-end torque and high-end output, a rotary valve is used inside the dual-passage intake manifold. During low/mid rpm,, the rotary valve is closed, while it opens during high rpm's. By varying the intake path length according to engine rpm, ample torque is gained at all rpm levels. Additionally, the rotary valve design is superior over past butterfly valve (flap) in that it reduces intake resistance. |

|

A Dual Intake Runner Manifold

Owners of 'regular' DC2s and DB8s will now know that their B18C intake manifold has dual intake runners and that a butterfly valve is used to disable/enable the shorter runner. This give the B18C a wide mid-range powerband. The K20A implements this as well but uses a newer rotary valve instead. The rotary valve is more like a ball-ish cylinder that can be rotated along its horizonal axis. Machined into this valve is a passage that matches the intake runners diameter. When aligned appropriately (by rotating the valve), this passage opens up a bypass path for the incoming air into the intake chamber. Otherwise the passage gets blocked by the body of the valve and air has to flow through the long runners. As Honda explained, the rotary valve implementation is superior to the traditional buttefly valve in that when properly aligned, there is no metal plate in the middle of the airflow path disrupting or restricting its flow.

|

||||||

| EGR Effect: By swirling back some of the exhaust air back into the combustion chamber, combustion temperature is lowered, and NOx output is reduced. |

The iVTEC operating principle

This section is the most complex of the whole article. As explained by Honda, we need to look at the operating combinations in a 3D mode now since we have introduced variable valve opening overlap in addition to the two stage cam profiles. Honda identifies 4 major cam variations for the K20A's iVTEC implementation. Of these, variations 1 to 3 are based on the so-called low cams and only variation 4 uses the high-cams. Note that the diagrams shows that VTEC is implemented only on the intake cam.

Now, note that there is an annotation indicating a 'mostly resting (intake) cam' in variations 1 to 3. This is the 'approximately 1-valve' operating principle of VTEC-E. Ie, one intake valve is hardly driven while the other opens in its full glory. This instills a swirl effect on the air-flow which helps in air-fuel mixture and allows the use of the crazy 20+ to 1 air-to-fuel ratio in lean-burn or economy mode during idle running conditions.

On first acquaintance, variations 1 and 3 seems identical. However, in reality they represent two different engine configurations - electronic-wise. Variation 1 is lean burn mode, the state in which the ECU uses >20:1 air-fuel ratio. VTC closes the intake/exhaust valve overlap to a minimal. Note that lean-burn mode or variation 1 is used only for very light throttle operations as identified by the full load Torque curve overlaid on the VTC/RPM graph. During heavy throttle runs, the ECU goes into variation 3.

Lean-burn mode is contained within variation-2 as a dotted area probably for the reason that the ECU bounces to-and-fro between the two modes depending on engine rpm, throttle pressure and engine load, just like the 3-stage VTEC D15B and D17A. In variation-2, the ECU pops out of lean-burn mode, goes back to 14.7 or 12 to 1 air-fuel ratios and brings the intake/exhaust overlap right up to maximum. This as Honda explains will induce the EGR effect, which makes use of exhaust gases to reduce emissions. I believe this is somewhat similar to the principle used in CVCC that Honda introduced on their early generation Civics in order to meet emissions objectives in the early 1970s.

I believe variation-3 is the mode where the ECU varies intake/exhaust opening overlap dynamically based on engine rpm for heavy throttle runs but low engine revs. Note also that variations 1 to 3 are used in what Honda loosely terms the idle rpm. For 3-stage VTEC engines, idle rpms takes on a much broader meaning. It is no longer the steady 750rpm or so for an engine at rest. For 3-stage VTEC, idle rpm also means low running rpm during ideal operating conditions, ie closed or very narrow throttle positions, flat even roads, steady speed, etc. It is an idle rpm range. The K20A engine implements this as well.

Variation-4 is activated whenever rpm rises and throttle pressure increases, indicating a sense of urgency as conveyed by the driver's right foot. This mode sees the wild(er) cams of the intake camshaft being activated, the engine goes into 16-valve mode now and VTC dynamically varies the intake camshaft to provide optimum intake/exhaust valve overlap for power.